Slot Hood Exhaust Design

What is covered in this document?

- Slot Hood Exhaust Design Software

- Commercial Kitchen Exhaust Hood Design

- Industrial Exhaust Hood Design

- Commercial Exhaust Hood Design

This document is part of a series of documents on industrial ventilation, and provides general information about hoods.

- Hoods

What is a hood?

- Hood “losses” Minimum duct design velocities. An increased slot velocity does not increase the hoods’ effectiveness. You can exhaust it.

- With an increase of C e, hood entry loss and% loss in velocity decreases. Cone hood is the better of the three given hoods with only 15% loss in velocity head. Problem: Find the static pressure of a hood if the velocity pressure is 4.5 'H 2 O and the coefficient of entry is 0.82. Solution: C e = (VP / SP) 1/2. Where C e is coefficient of entry.

A hood - correctly called a local exhaust hood - is the point where contaminated air is drawn into the ventilation system. The sizes and shapes of hoods are designed for specific tasks or situations. The air speed (velocity) at the hood opening and inside the hood must be enough to catch or capture and carry the air contaminants. To be most effective, the hood should surround or enclose the source of contaminant or be placed as close to the source as possible.

The volumetric exhaust flow rate through the system was one-half that which would have been required for a commonly used slot design. This reduction in exhaust volume was due to partial enclosure of the slot, which reduced the handling of uncontaminated air. The shape of the hood, its size, location, and rate of airflow each play an important role in design considerations. Each type of hood has specific design requirements, but several general principles apply to all hoods: The hood should be placed as close as possible to the source of.

What are the common types of hood?

The three common classes of hoods are:

- Enclosing.

- Receiving.

- Capturing.

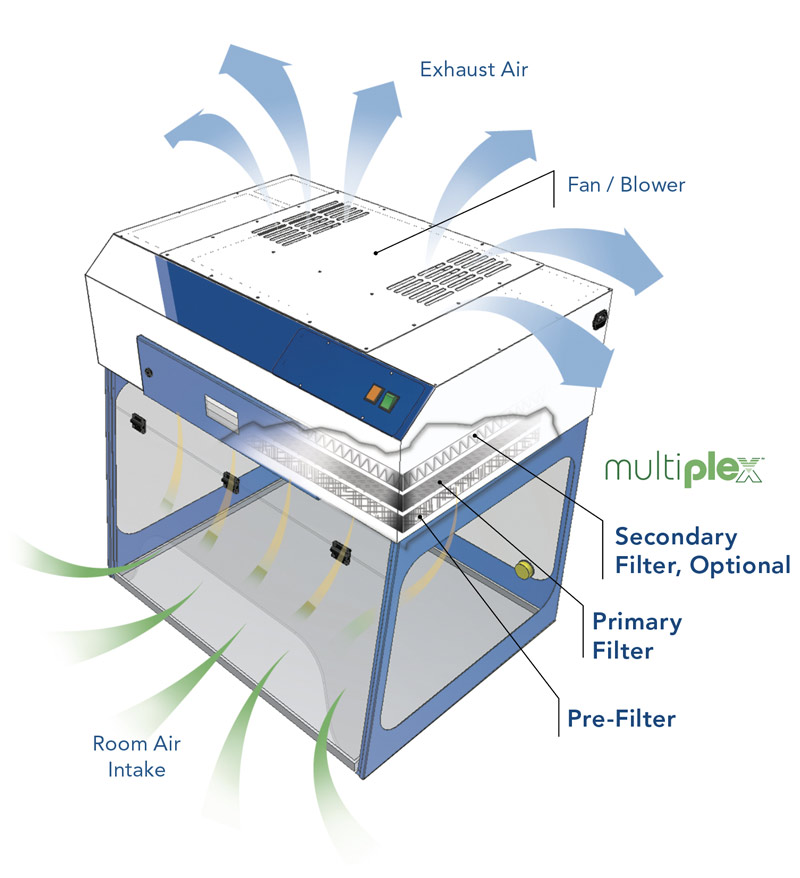

Enclosing Hood

Enclosing hoods, or 'fume' hoods, are hoods surrounding the process or point where the contaminants are generated. Examples of completely enclosed hoods (all sides enclosed) are glove boxes and grinder hoods. Examples of partially enclosed (two or three sides enclosed) hoods are laboratory hoods or paint spray booths. The enclosing hood is preferred whenever possible.

Receiving Hood

These hoods are designed to 'receive' or catch the emissions from a source that has some initial velocity or movement. For example, a type of receiving hood called a canopy hood receives hot rising air and gases as shown in Figure 2. An example is a canopy hood located over a melting furnace.

Figure 2

Receiving Hood

Capturing Hood

These hoods are located next to an emission source without surrounding (enclosing) it. Examples are a rectangular hood along the edge of a tank (as shown in Figure 3) or a hood on a welding or grinding bench table (figure 4) or a downdraft hood for hand grinding bench (figure 5).

Figure 4

Capturing hood for welding or grinding bench

What is meant by 'capture velocity'?

The ventilation system removes contaminants by 'pulling' the air (and the contaminant) into the exhaust hood and away from the worker or the source. Airflow toward the hood opening must be fast or high enough to 'catch and transport' the contaminant until it reaches the hood and ducts. The required air speed is called the 'capture velocity'.

Any air motion outside of the hood and surrounding area may affect how the air flows into the hood. The ventilation system will require a higher airflow speed to overcome air disturbances. As much as possible, the other sources of air motion should be minimized or eliminated for the ventilation system to work effectively.

Common sources of external air movement include:

- Thermal air currents, especially from hot processes or heat-generating operations.

- Motion of machinery such as grinding wheels, belt conveyor, etc.

- Material motion such as dumping or filling.

- Movements of the operator.

- Room air currents (which are usually considered 50 fpm (feet per minute), but may be much higher).

- Rapid air movement caused by spot cooling and heating equipment.

Where the contaminant is released with practically no other air currents in a room, the recommended capture velocity is generally around 0.5 m/s (100 feet per minute (fpm)). How fast is 100 fpm? Blowing lightly on your hand so that you can just barely feel air movement is about 100 fpm. It is easy to see how it will take very little air movement from other sources to affect how well a hood can capture contaminants. (See Figure 6).

In situations, such as grinding for example, where the contaminants are released in the air at high speed and where there is a rapid air circulation in the room, the necessary capture velocity may be 5 to 10 times higher.

What are the general rules for hood design?

The shape of the hood, its size, location, and rate of airflow each play an important role in design considerations. Each type of hood has specific design requirements, but several general principles apply to all hoods:

- The hood should be placed as close as possible to the source of contamination, preferably enclosing it. The more completely enclosed the source is, the less air will be required for control. The required airflow rate varies with the square of the distance from the source as shown in Figure 7.

- The air should travel from source of the contaminant and into the hood with enough velocity (speed) to adequately capture the contaminant.

- The hood should be located in a way that the operator is never between the contaminant source and the hood.

- The natural movement of contaminants should be taken into consideration. For example, a hood should be placed above hot processes to trap rising gases and heat. A grinding wheel or woodworking machine should be equipped with a partial enclosure to trap the flying particles where they spin off.

- Flanges or baffles should be used around the hood opening to increase the capture effectiveness and reduce ventilation air requirements.

Figure 7

If a hood is moved from two inches away from a source to four inches away (twice the distance), the airflow required to provide the same degree of capture will be four times greater.

How do I know which type of hood is adequate for the process?

The hood should be selected according to the characteristics of the process to ensure that the worker’s exposure to airborne contaminants is minimal.

The following table contains a comparison of the three types of hoods.

| Table 1 Comparison of Hoods | |||

|---|---|---|---|

| Capturing and Receiving Hoods | Enclosing Hoods | ||

| Recommended | Disadvantages | Recommended Use | Disadvantages |

| Contaminant released with no speed Contaminant released at locations with minimal speed cross-draft conditions Note: the source must be located within the effective range of the hood | Performance is reduced by:

| Generation of high amount of contaminant Very toxic contaminant Contaminant released with high speed High speed cross-draft conditions All other conditions where capture / receiving hoods are effective | High cost More complicated design Occupy more of the workplace space |

How do I know if a hood is working as designed?

The ASHRAE 110 (test) is the recognized method for evaluating the performance of fume hoods. A qualified person should do the testing.

Sometimes it seems that almost everything in a laboratory is governed by an alphabet soup of government agencies and regulations. We are all familiar with the acronyms OSHA, EPA, NIOSH, and FDA and how they impact our labs. It’s the same with fume hoods. Their installation, operation and maintenance are guided by a variety of governmental and industry organizations. Fortunately, understanding who and what determines proper fume hood operation is not as difficult as it might first seem.

Codes, Standards and Recommended Practices

The following are the primary organizations and standards regarding fume hoods:

–OSHA Part 1910.1450. OSHA stands for Occupational Safety and Health Administration. The agency regulations regarding fume hood operation are listed in the Code of Federal Regulations Volume 29 Part 1910.1450. This code addresses several aspects of laboratory design and operation. Regarding hoods it is primarily concerned with airflow at the face of the hood, monitoring, maintenance and exhaust.

–ANSI/ASHRAE 110-1995. Method of Testing Performance of Laboratory Fume Hoods. This standard is published by the American National Standards Institute and the American Society of heating, Refrigerating and Air Conditioning Engineers, Inc. It concerns itself primarily with methods of testing fume hoods to check their operation.

–ANSI/AIHA Z9.5. Titled “The American National Standard for Laboratory Ventilation” this standard is published by ANSI and the American Industrial Hygiene Association. It covers a variety of lab ventilation issues including hood monitoring, face velocities and exhaust.

–NFPA 45. This standard is prepared by the National Fire Protection Association. It recommends hood construction, location, fire protection, specialty hoods, identification, inspection, testing and maintenance and exhaust.

–SEFA 1.2-1996. SEFA is the Scientific Equipment & Furniture Association. Its publication “Laboratory Fume Hoods Recommended Practices” covers design requirements of hoods, face velocities and testing.

Special Concerns

Items of immediate interest to lab personnel that are addressed in the codes and standards include:

- Air flow

- Monitoring/Alarms.

- Maintenance/Inspection.

- Exhaust.

1. Air Flow

Proper air flow at the face of the hood is probably the most common cause of confusion regarding fume hood operation. Here are what the codes and standards say:

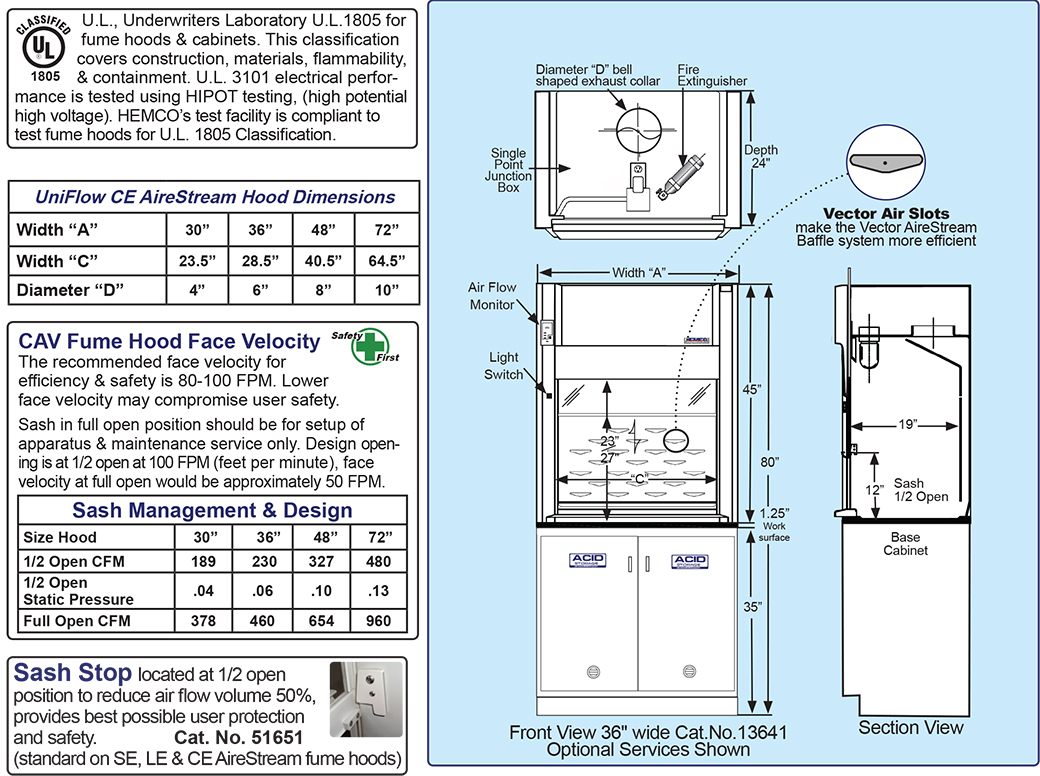

OSHA: “General air flow should not be turbulent and should be relatively uniform throughout the laboratory, with no high velocity or static areas; air flow into and within the hood should not be excessively turbulent; hood face velocity should be adequate. (Typically 60-110 fpm.)”

ANSI/AIHA Z9.5: “Each hood shall maintain an average face velocity of 80-120 fpm with no face velocity measurement more than plus or minus 20% of average.”

SEFA: “Face velocities of laboratory fume hoods may be established on the basis of the toxicity or hazard of the materials used or the operations conducted within the fume hood. Note: Governmental codes rules and regulation may require specific face velocities. A fume hood face velocity of 100 fpm is considered acceptable in standard practice. In certain situations face velocity of up to 125 fpm or as low as 75 fpm may be acceptable to meet required capture velocities of the fume hood.”

2. Monitoring/Alarms

Many older labs are equipped with fume hoods that do not have air flow monitoring devices. The type of device is not specified, but according t the following codes and standards if you’re putting in a hood or remodeling an older one they are now a requirement.

OSHA: “….each hood should have a continuous monitoring device to allow convenient confirmation of adequate hood performance before use. If this is not possible, work with substances of unknown toxicity should be avoided or other types of local ventilation devices should be provided.”

ANSI/AIHA Z9.5: “New and remodeled hoods shall be equipped with a flow-measuring device.”

NFPA 45: “New and remodeled hoods shall be equipped with a flow-measuring device.

3. Maintenance/Inspection

As with all equipment maintenance is important to proper operation.

OSHA: “Quality and quantity of ventilation should be evaluated on installation, regularly monitored (at least every 3 months), and re-evaluated whenever a change in local ventilation devices is made.”

ANSI/AIHA Z9.5: “A routing performance test shall be conducted on every fume hood at least annually or whenever a significant change has been made to the operational characteristics of the system”

NFPA 45: “When installed or modified and as at least annually thereafter, laboratory hoods, laboratory hood exhaust systems, and laboratory special exhaust systems shall be inspected and tested.”

Slot Hood Exhaust Design Software

NFPA 45: “Special use laboratory hoods and special use local exhaust systems shall be identified to indicate their intended use.” “A sign shall be affixed to each hood containing the following information from the last inspection: Inspection interval, Last inspection date, Average face velocity, location of fan that serves hood, Inspectors name. Exception: In lieu of a sign, a properly maintained log of all hoods giving the above information shall be deemed acceptable.”

4. Exhaust

The old expression “out of sight, out of mind” is often apt when discussing fume hood exhaust. Lab personnel rarely crawl up onto the roof to check out their exhaust fans and stacks. Knowing what the standards, rules and codes have to say on the exhaust can come in handy if you’re experiencing odors in the lab or if you’re considering a renovation or new facility.

Commercial Kitchen Exhaust Hood Design

ANSI/AIHA Z9.5: “Discharged in manner and location to avoid re-entry into the laboratory building or adjacent buildings at concentrations above 20% of the allowable concentrations inside the laboratory under any wind or atmospheric conditions.” Exhaust stack: “Be in a vertical up direction at a minimum of 10 feet above the adjacent roof line as so located with respect to opening and air intakes of the laboratory or adjacent buildings to avoid re-entry.”

Industrial Exhaust Hood Design

NFPA 45: “Air exhausted from laboratory hoods and other special local exhaust systems shall not be re-circulated.” “Air from laboratory units and laboratory work areas in which chemicals are present shall be continuously discharged throughout systems maintained at a negative pressure relative to the pressure of normally occupied areas of the building.

Commercial Exhaust Hood Design

If you have any questions feel free to give me, Bruce Ciloski, a call. You can reach me at 832.256.0014 or email me at bruce@laboratorydesign.com.